New Business from Down Textile Industry’s Side Streams

JoutsenHackathon

The goal of the JoutsenHackathon is to find new ideas, commercial partnerships, and new methods of utilization for the side streams and waste materials formed in down textile production in Joutsen Finland oy’s factories in Estonia and in Finland. The aim of the Hackathon is to activate new players and industries in innovating products utilizing textile and down waste and replacing part of the virgin raw materials with recycled materials.

What is it about

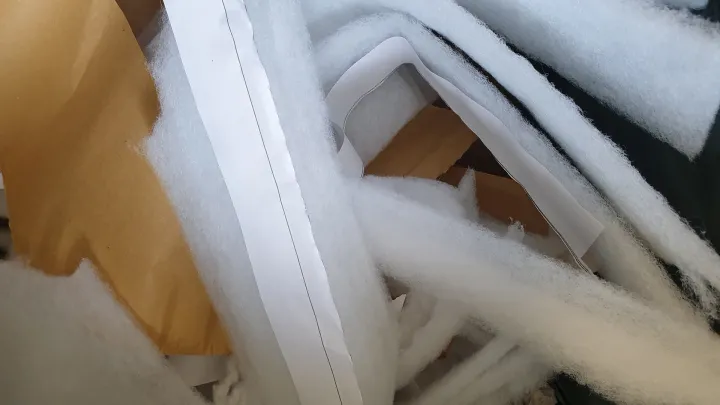

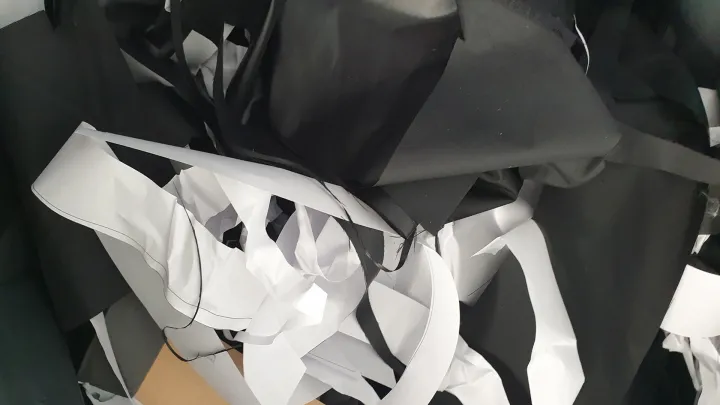

The side streams generated in the production of Joutsen Finland oy's down textile products (e.g., down jackets, down blankets) are divided into cutting waste (polyamide, polyester), dust and the fraction formed by feathers and impurities. In production, a lot of attention is paid to making sure that as much of the material as possible is utilized and that the generation of waste is kept to a minimum. Despite that, a total of approx. 5 t/y of cutting waste, 4 t/y of feathers and impurities, and approx. 1.5–2 t/y of dust are generated as unutilized side stream. Feather and impurities fraction as well as dust are very light, so the volume of generated waste is large. Currently, in the absence of other utilization methods, the material goes to energy waste and incineration.

Cutting waste (fabric, wadding) mainly contains polyester and polyamide materials. There is pattern paper among the waste, and the material has a non-toxic water repellency treatment according to standards. Dust is created when dust, dander, grease, and animal proteins are removed from the down during the washing process. The trash feather and impurities fraction consist of feathers that are too large and impurities (e.g., small stones) that are not suitable for down products.

Feather and impurities fraction as well as dust are very light, so the volume of generated waste is large. A dust bag with a volume of 0.7 m3 weighs approx. 25 kg, and a 130-liter dust bag approx. 2–5 kg. The feather and trash fraction comes in different colors, white, gray, and varied color mix.

Joutsen Finland oy's factories are located in Riihimäki, Finland and in Märjamaa, Estonia (approx. 70 km from Tallinn). Most of the side streams of the production are generated in Estonia (in Finland approx. 0–200 kg/year of cutting waste, approx. 50–100 kg/year of waste feathers and trash and approx. 500 kg/year of dust from feather processing).

The goal of the Hackathon is to find one or more partners who would be able to regularly receive materials generated as a side stream of textile production. Possible uses of the materials could be, for example, utilization in insulation, bedding, as filling material or, for example, in fishing equipment. So, there are many possibilities even outside the textile industry, and the solution to utilizing the material may be found in a completely different industry.

The project is funded from the budget of REACT-EU as part of the Union's response to the COVID-19 pandemic.

What JoutsenHackathon?

Myrsky Project, in cooperation with Joutsen Finland oy, are opening a Hackathon, the aim of which is to find new ideas, commercial partners and utilization methods for the side streams and waste fractions generated in connection with the manufacture of Joutsen Finland oy's textile products. The aim of the Hackathon is to activate new players and industries in innovating products from textile and down waste and replacing part of the virgin raw materials with recycled materials. Joutsen Finland oy offers the teams that presented the best ideas cooperation in the further development of ideas and new services, as well as in marketing to their own customers and networks.

Joutsen Finland oy Founder of the family business, Marius Pedersen, once defined Joutsen Finland as: The goal is to manufacture high-quality products, that create a great mood for their users – in a working community with a good spirit. That thought has driven all our choices. It guides us to genuinely care about the customer, the well-being of animals, our associates, employees, the community, and the environment. The world has changed in many ways; our work has expanded over the years and our activity is much larger than in the beginning. Our goal to this day is to listen to the customer and manufacture long-lasting and high-quality Joutsen products that are easy to maintain. Joutsen does not use down plucked from living animals and operates in accordance with EU legislation and ethical guidelines. More information about the down certificate.

#circulareconomy #recycledmaterials #sidestreams #industrialresidues #textilewaste #textileindustry #sustainability #jamk #storm2023 #react #esr #resilience #greentransition #sustainabledevelopment

Organiser

Myrsky project STORM [MYRSKY] – Businesses’ Resilience, Green Transition, and Digitalization in Western Finland

The goal the Myrsky [Storm] project is to create rapid actions for businesses in the themes of green transition, resilience, and digitalization through collaboration among universities of applied sciences. The funding source of the project is European Social Fund (ESF) 2014-2020. The project is financed from the appropriations of the REACT-EU instrument, as part of the actions taken by the European Union due to the covid-19 pandemic. Suomen Yrittäjät [Entrepreneurs in Finland] is the partner of the project.

Read more about Myrsky [Storm] project:

STORM – Businesses’ Resilience, Green Transition, and Digitalization in Western Finland

BioPaavo by JAMK is a Bioeconomy Business Accelerator that aims to create new business and globally significant solutions to combat climate change in the international bioeconomy environment. BioPaavo's key tasks are to develop bioeconomy business and create sustainable business based on new innovations, utilizing new technologies and digitalization, developing abilities and know-how, and building business networks and ecosystems.

The project is funded from the budget of REACT-EU as part of the Union's response to the COVID-19 pandemic.